2D fiber laser processing machine achieves high speed and high-quality cutting of various materials and thicknesses

- Resonator is available in 3.0 kW, 4.0 kW, 6.0 kW, 10.0 kW, 15.0 kW, and 20.0 kW

- New MAZATROL SmoothLx CNC Control

- Increased Accessibility and Ease of Operation

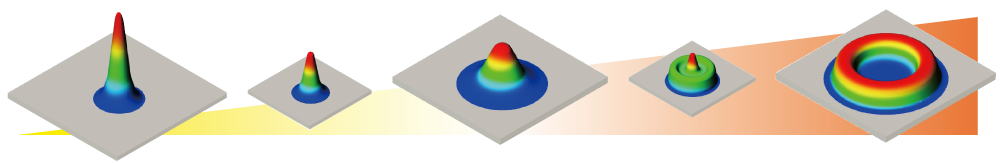

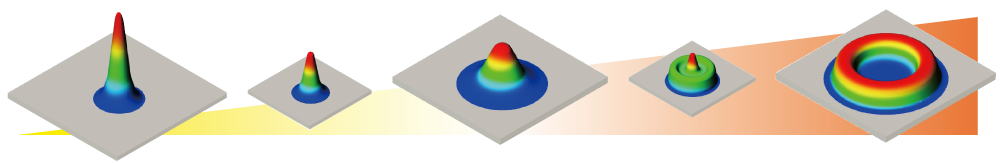

Beam Diameter Control / Variable Beam Mode*

The Beam Diameter Control function automatically adjusts to the optimum beam diameter for each material and thickness. Machines are also equipped with Variable Beam Mode function which controls the divergence angle of the laser beam from the fiber resonator. Together, these two technologies provide faster cutting speed for thin material as well as superior cutting quality for thick material.

*When equipped with laser oscillator compatible with Variable Beam Mode

Adjusting beam shape depending on the sheet thickness

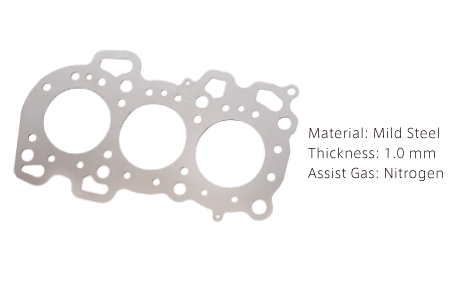

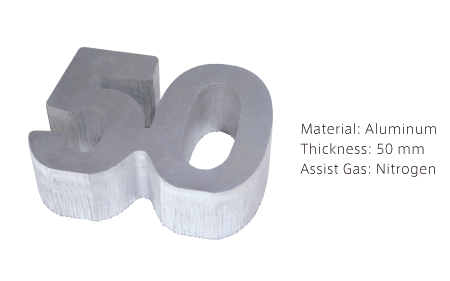

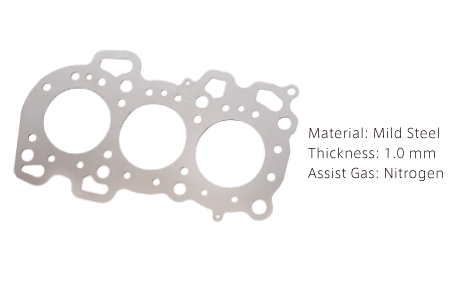

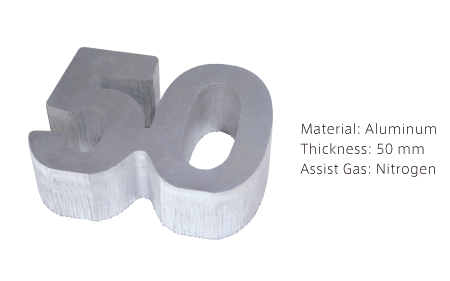

Sample Work

Resonator Power Level |

3.0 kW |

|---|

Control Function |

Beam Diameter |

〇 |

Beam Shape |

- |

Purpose |

Thin metal cutting |

Resonator Power Level |

4.0 kW |

|---|

Control Function |

Beam Diameter |

〇 |

Beam Shape |

- |

Purpose |

Mid - Thick metal cutting |

Resonator Power Level |

6.0 kW, 10.0 kW, 15.0 kW, 20.0 kW |

|---|

Control Function |

Beam Diameter |

〇 |

Beam Shape |

〇 |

Purpose |

Thick metal cutting |

Wide Open Door

The machine’s front and side access doors reduce the floor space needed for installation and make it easier for operators to load and unload material.

The front door offers full width opening of 1200 mm, and the side doors provide a full length opening of 3210 mm.

Integrated Nozzle Camera?(Option)

A camera to check the nozzle center location can be added next to the nozzle holder. This enables an operator to adjust the nozzle center location by rotating the dial on the torch while watching the image on the CNC display.

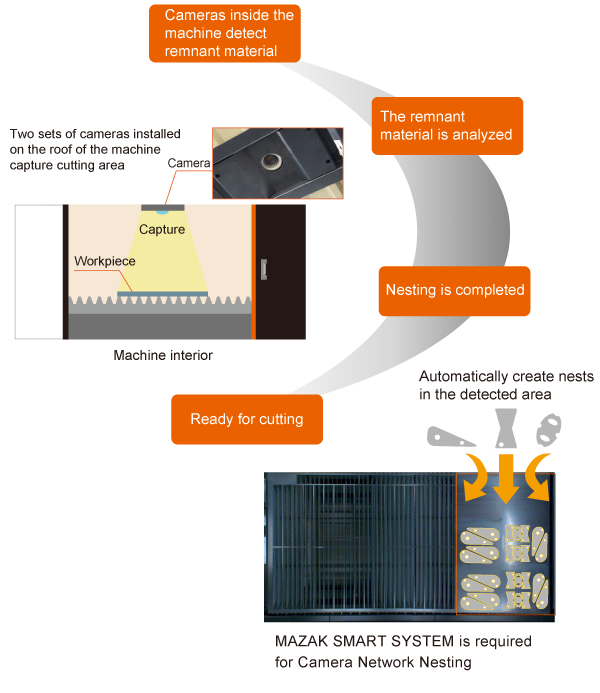

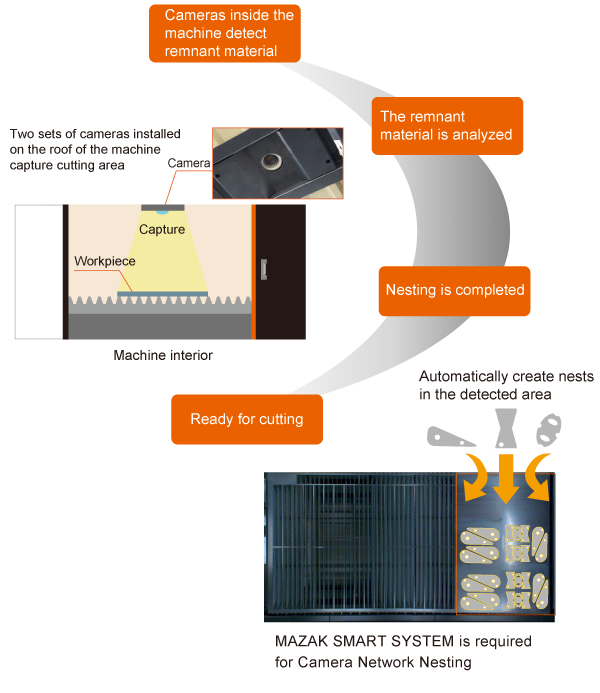

Camera Assisted Part Nesting?(Option)

The nesting feature automatically determines how to arrange parts for optimal cutting on remnant material.

The latest CNC Control

Wide Screen and Flat Design

Wide Screen and Flat Design

The wide screen enables operators to view nesting at a glance. Additionally, operators can easily zoom in and out using the touch screen display. Operational buttons feature a flat design and icons for intuitive performance. The Emergency Stop and Rotary Switch buttons are positioned prominently to ensure easy access.

Photo:Dual Monitor(option)

Environmental Activities of OPTIPLEX 3015 NEO

Reduction in Energy Consumption

Fiber laser processing machine reduces 60 % of energy consumption in comparison to the previous model (CO

2?laser processing machine).

Reduction in Gas Consumption

Assist gas consumption is reduced by 75 % with the new torch and nozzle in comparison to the previous model.